PRODUCTION

Industrial

tools

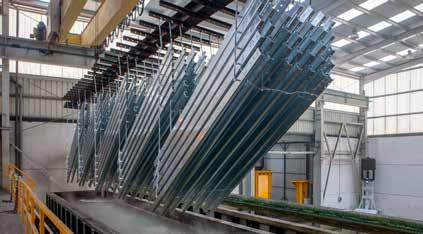

AdiWatt has two production plants located in SPAIN and FRANCE, with an overall production capacity in excess of 700/MW/year (2017). Our machines are robotized to maximize our productivity and reduce production costs, enabling us to increase our competitiveness and offer our customers the best prices to meet their needs. AdiWatt integrates all stages of steel manufacturing and processing to produce all its solar structures. We start with the coil supplied directly from the steel mill, which we cut into strips and shape by profiling before carrying out the bending, stamping and cutting stages. The steel is then hot-dip galvanized or powder-coated with epoxy paint, if required by the project specifications. In our logistics warehouse, we have two container-loading platforms for agile, safe and optimal loading of containers from 20 to 40 tons. To respond quickly and efficiently to customer needs, AdiWatt holds an average stock of 15,000 tonnes of steel in various grades and thicknesses. Since 2015, AdiWatt has been one of the pioneers in introducing Magnelis® anti-corrosion coatings according to EN 10346: 2015 into its manufacturing process.

production

Engineering

office

AdiWatt designs the support structure and adapts it specifically to the particular conditions of each site, to enable optimum use of the area. To ensure that the proposed photovoltaic system functions properly, a specific analysis is carried out according to the needs of each customer. This study includes the static calculation of horizontal and vertical loads, an examination of their behavior under external conditions: wind, snow, seismic load... and the assembly of the structure through various mechanical systems to avoid stress and erosion over time.